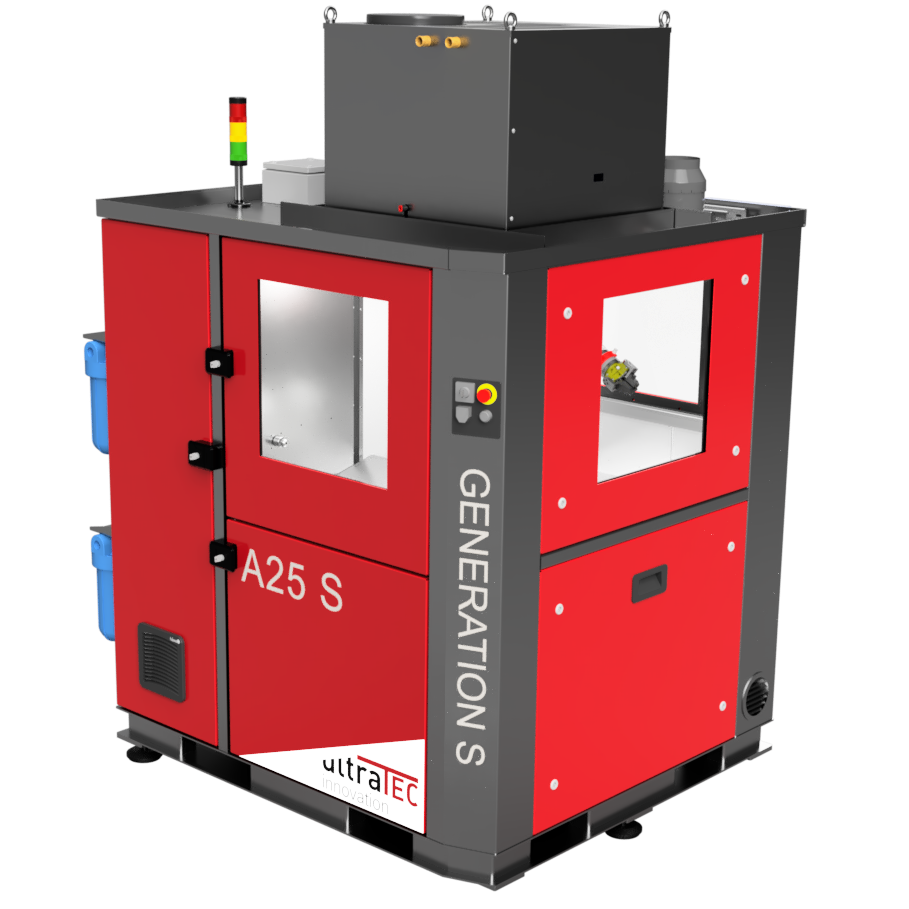

Ultrasonic deburring machine A25 S

Our flexible system for complex components.

For complex components up to a max. component weight of 7kg and a max. component size of approx. 150x150x150 mm.

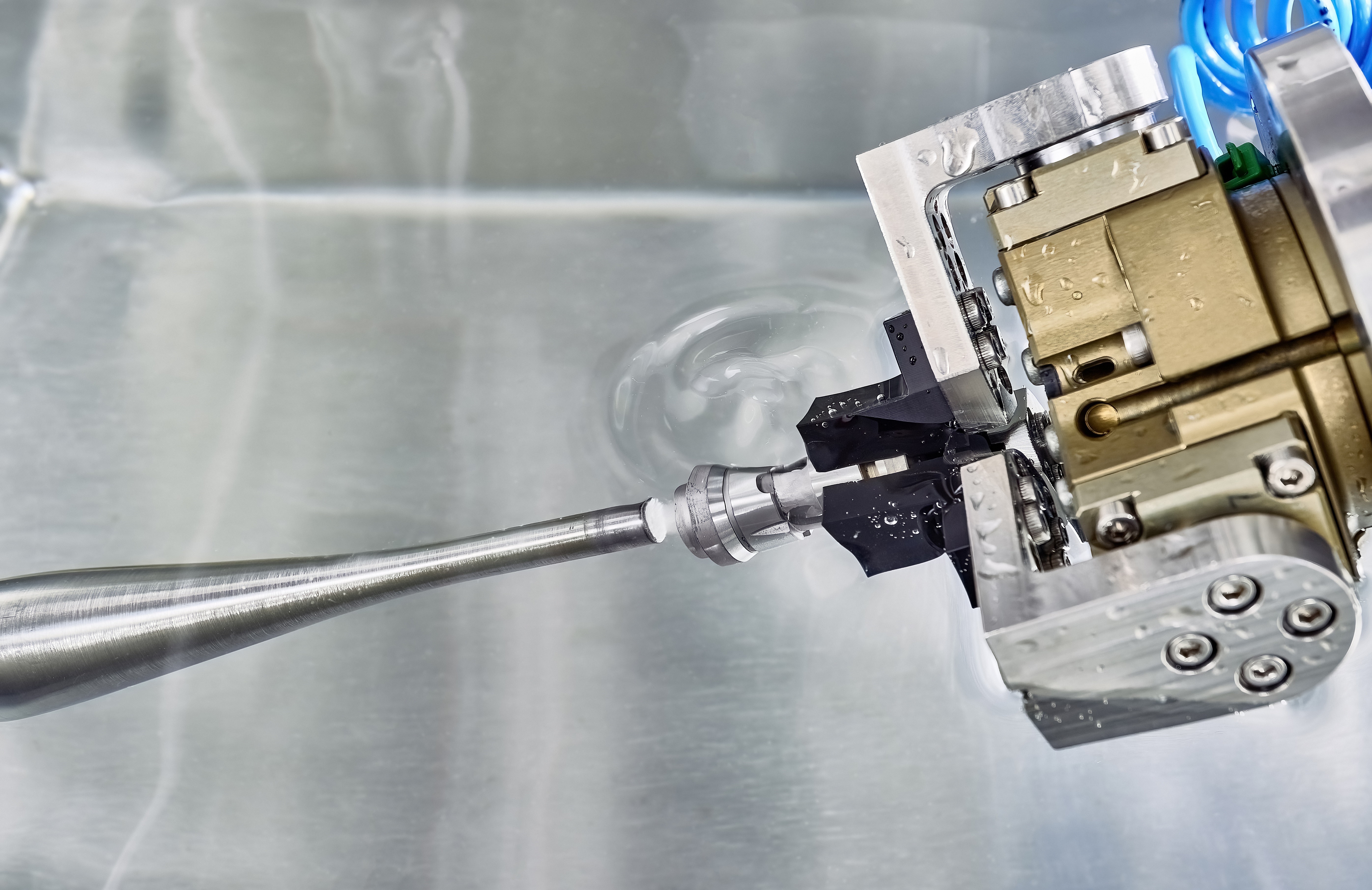

Two or optionally three sonotrodes installed in the process water basin enable the processing of complex components with different sonotrodes in one set-up. By arranging the sonotrodes at different angles, the A25 S impresses with its high degree of flexibility. The system enables unmanned production with up to 6 automatic drawers (optional).

A 6-axis industrial robot for component handling stands on a welded steel machine bed, which is partially filled with mineral concrete. This gives the machine maximum stability. The housing consists of a welded steel housing. The A25 S ultrasonic deburring system can be equipped as follows:

- Industrial robot,

- 2 or up to 3 sonotrodes (optional) in the process water basin at different angles and heights,

- 3 or 6 drawers (optional) for component supply,

- Regripping station (optional),

- Blow-off station for drying the components,

- Compressed air spindle for mechanical processing (optional),

- Digital twin (optional)

Machine dimensions A25 S

| Transport | in operation (installation dimensions) | |

|---|---|---|

| Width in mm | 1.350 | 1.350 |

| Length in mm | 1.800 | 1.800 |

| Height in mm | 2.150 | 2.250 |

| Total weight in kg | 1.150 | |

| Max. component size in mm | 150 x 150 x 150 | |

| Max. component weight in kg | 7 | |

| Content process water basin in liter | 36 |

Connections

Electric:

400V 16A; Total connected load without options 6,2 kVA

Fresh water connection

Waste water connection

EDP-Connection