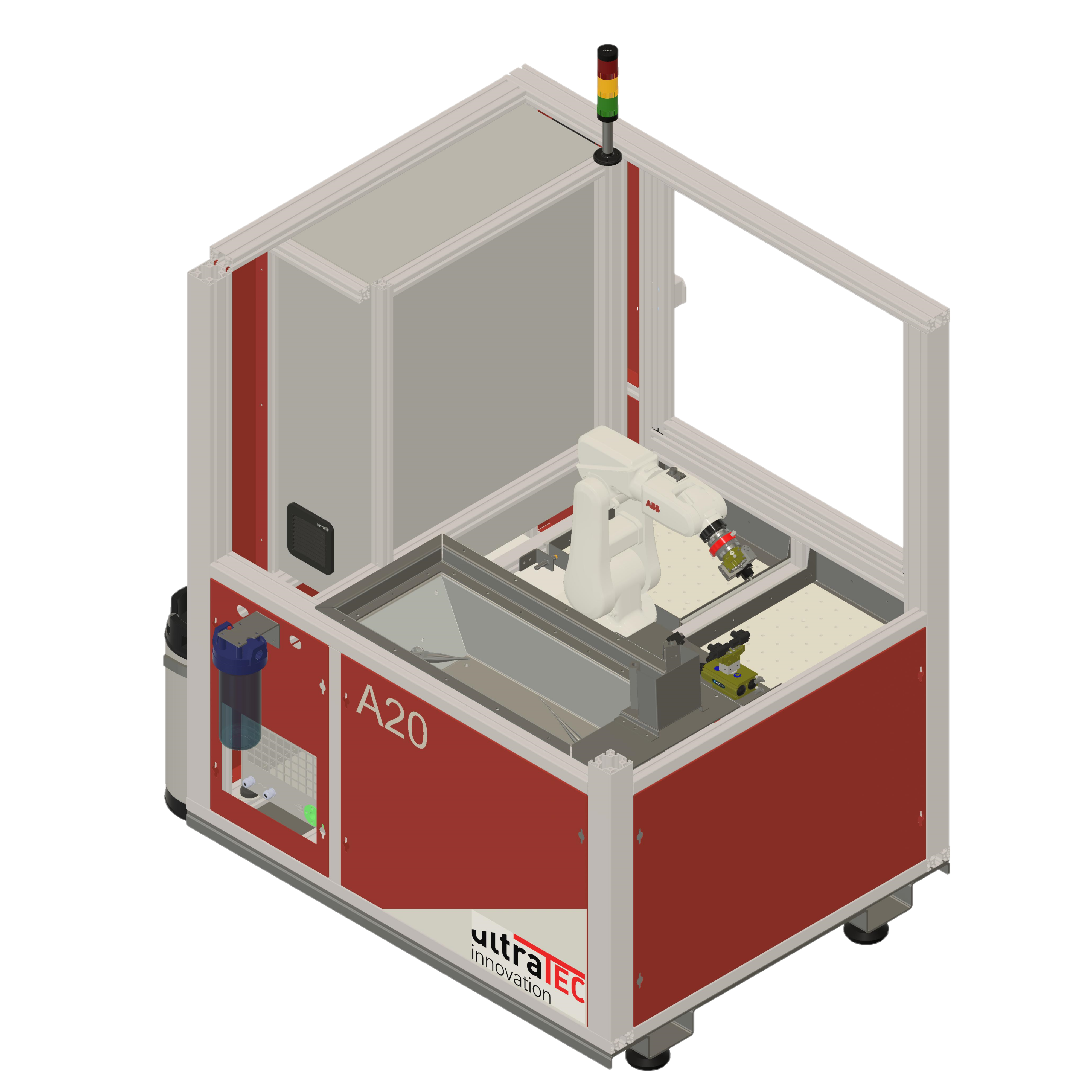

Ultrasonic deburring machine A20 C

Our compact machine.

For complex components up to a max. component weight of 1.5kg and a max. component size of approx. 100x100x100 mm.

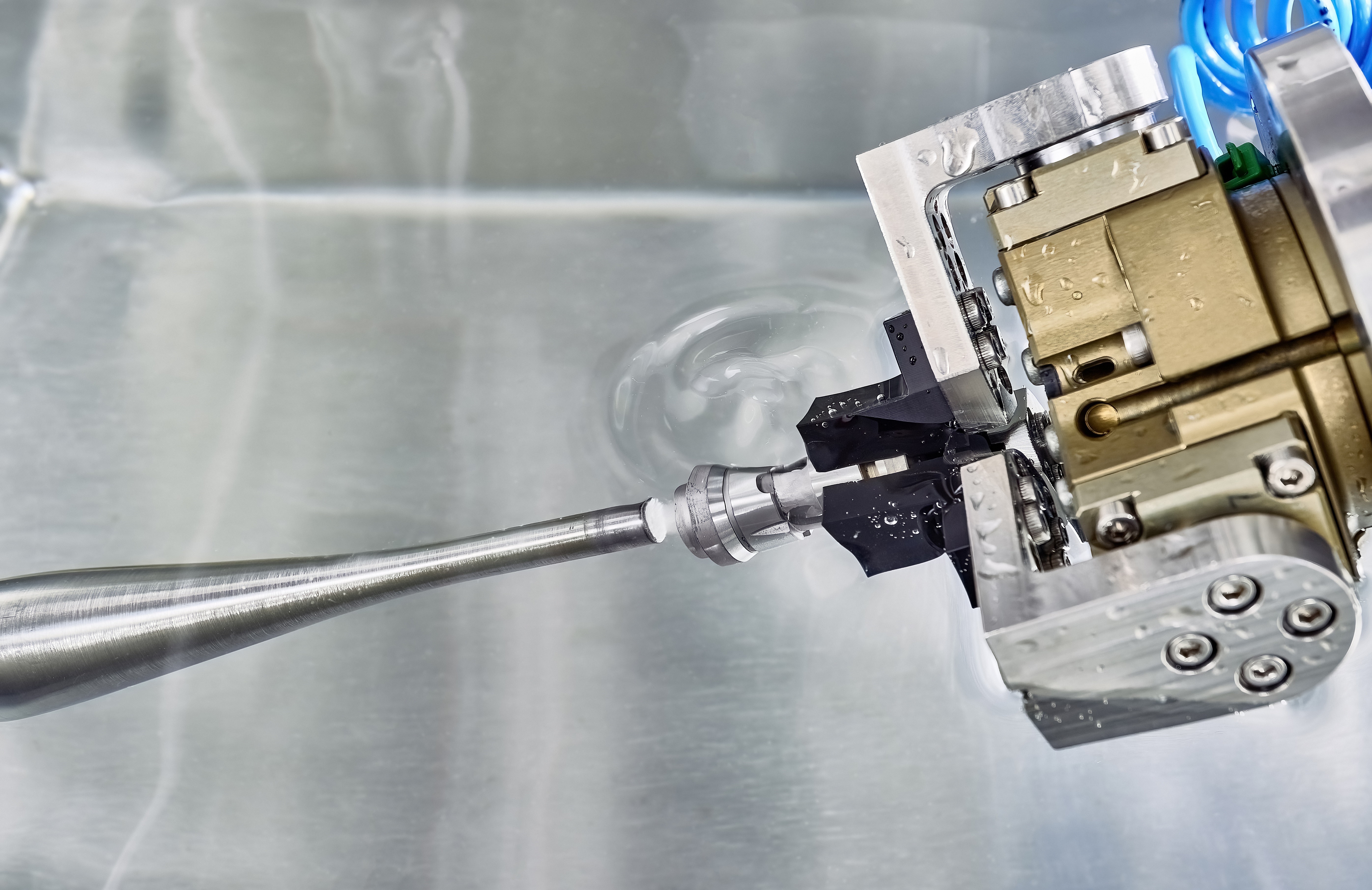

Two sonotrodes installed against each other in the process water basin enable the processing of complex components with different sonotrodes in one clamping.

The machine impresses with its compact design and comes with 2 drawers for automated component feeding. A 6-axis industrial robot for component handling stands on a welded steel machine bed, which is partially filled with mineral concrete. This gives the machine maximum stability. The housing is made of high-quality aluminium profiles. The compact A20 C ultrasonic deburring system can be equipped as follows:

- Industrial robot,

- 2 sonotrodes in the process water basin,

- 2 drawers for component supply,

- Regripping station (optional),

- Blow-off station for drying the components,

- Compressed air spindle for mechanical processing (optional),

- Digital twin (optional)

Machine dimensions A20 C

| Transport | in operation (installation dimensions) | |

|---|---|---|

| Width in mm | 1.250 | 1.250 |

| Length in mm | 1.500 | 1.500 |

| Height in mm | 1.850 | 2.100 |

| Total weight in kg | 800 | |

| Max. component size in mm | 100 x 100 x 100 | |

| Max. component weight in kg | 1,5 | |

| Content process water basin in liter | 30 |

Connections

Electric:

400V 16A; Total connected load without options 5,6 kVA

Fresh water connection

Waste water connection

EDP-Connection